Our production departments

Department

Logs and Logs slicing

G&F Veneers, starting in 1993, began its production journey by starting with the raw material, turning logs into veneer sheets. This forward-looking and straightforward approach allows us to obtain the cuts, lengths, and qualities to be competitive by adapting to various market demands. Flexibility extends to the various levels of in-house production, on the processed product destined for craft and industrial customers.

Department

Warehouse

Material selections are an expression of our experience gained over many years of operation.

Our expertise enables us to select materials specifically for the industry sector from our stock.

We follow the demands of both medium and large enterprises on a daily basis.

In our stock you will find different essences from various countries, observing all the necessary certifications for their importation.

Service and availability to the customer are the mission of our warehouse.

Department

Spliced

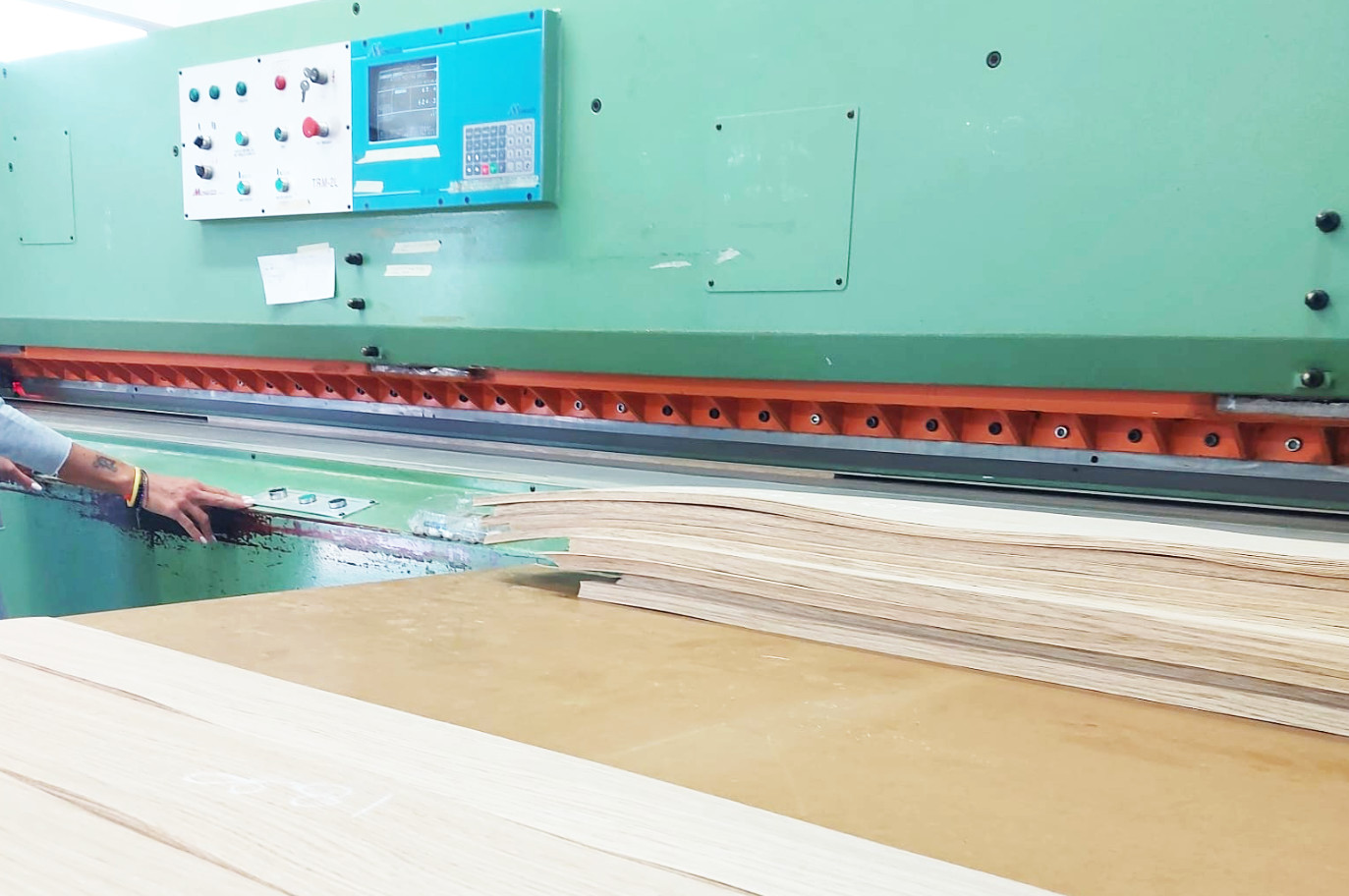

G&F matures the experiences gained as a splicing department and is currently at the forefront of technology and professionalism.

The production department is the beating heart of our business and is a reference in the industry nationwide.

It proposes and fulfills the various customer requirements on several levels, with a process that starts from the selection of materials and then moves on to cutting, coloring and finally joining them with different techniques.

Our flexibility allows us to meet different needs as we have departments dedicated to both just-in-time and large series.

Area

Wood dyeing

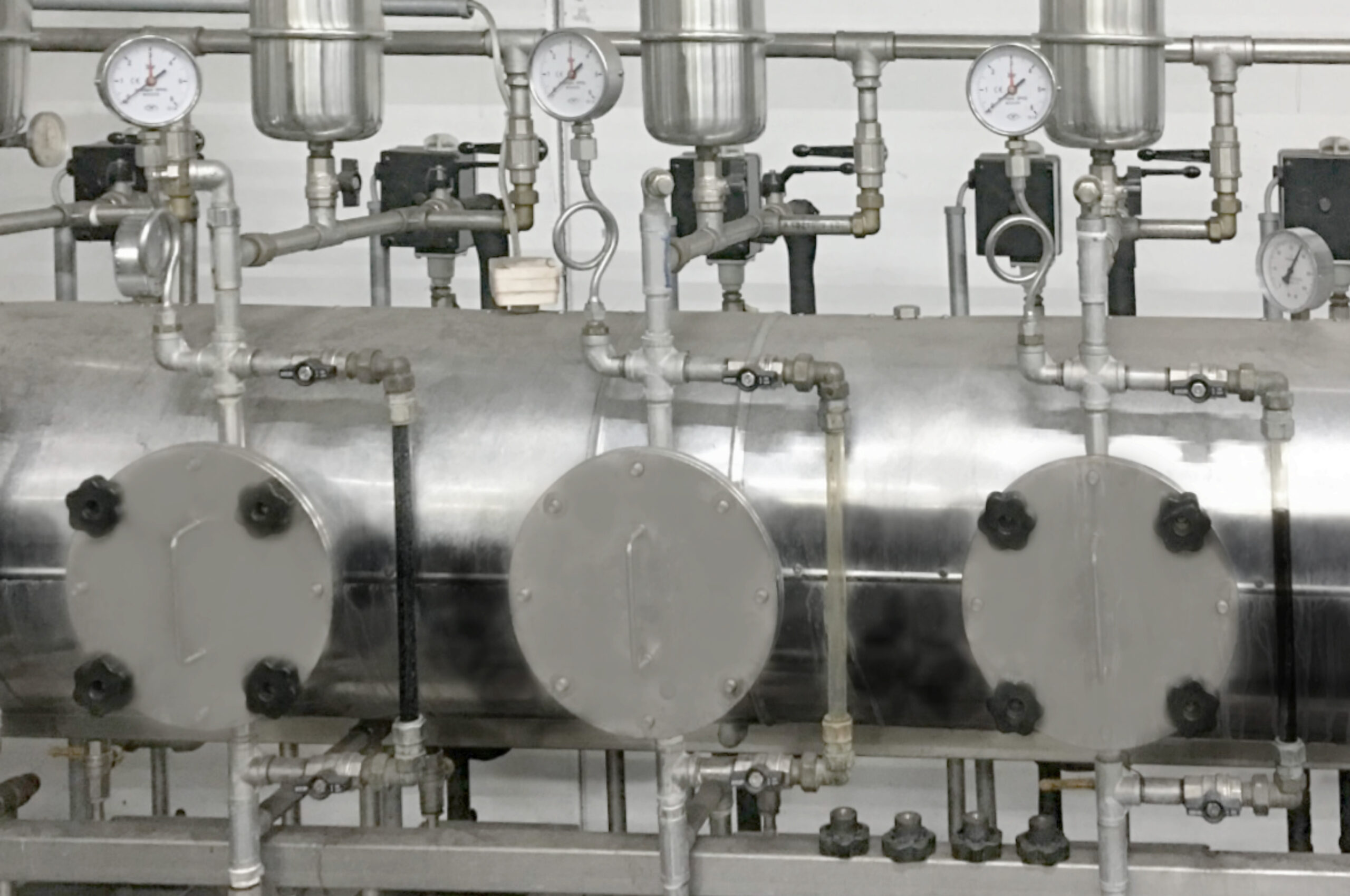

G&F veneers has a modern department internally dedicated to in-tank dyeing of veneer sheets and holds through the TINGE brand an extensive collection of products. Our veneers are dip-dyed in the tank, resulting in a rich range of colors that can be customized by the customer. The thermo-smoking department makes it possible to obtain natural and special colors on different wood species. Our thermo-smoking department is also available for contract processing on thicknesses ranging from 0.6 up to 30mm.

Area

Pressing and sanding

At the customer's request at GF Tranciati, paper backings can be applied to the spliced sheets. In addition, we also offer a sanding service. Attention and care to detail allows us to guarantee and maintain consistent quality standards, an increasingly preponderant aspect of the customer-supplier relationship.

Area

Pantographs and brushing

The 3D dedicated department was born out of the need and research for new forms of design, and is constantly evolving in terms of stimulating innovations for the customer. The applied technology involves the use of essences of various thicknesses that allow milling from solid wood through the use of dedicated machining centers. We are also equipped with technologies for the application of veneer sheets to various shapes with vacuum techniques for specific client-tailored customization. Panel finishing is completed with brushing carried out by our dedicated plant.

Area

Technical Office

Knowledge of materials and processes, together with professional expertise, create that fundamental value for every customer need.

Our technical department provides valuable customer support for shared project growth.

Our technical department provides valuable customer support for shared project growth.

Our

Services

We provide a wide range of services tailored to customer needs. Contact us for more information on how we can help you.

Bespoke just-in-time on customer request

Panel squaring and edging

Panel drilling

Brushing service

Certifications

Ask for our FSC® products